Common Problems and Solutions of BOPP Pre-coating Film

04

/

11

2023

Industry trends for various substrates of pre-coated films

03

/

15

2023

Pre-coating film industry development history and product classification

02

/

02

2023

Pre-coating film-green environmental protection printing new materials

01

/

22

2023

Insulation film should be how to choose

09

/

01

2022

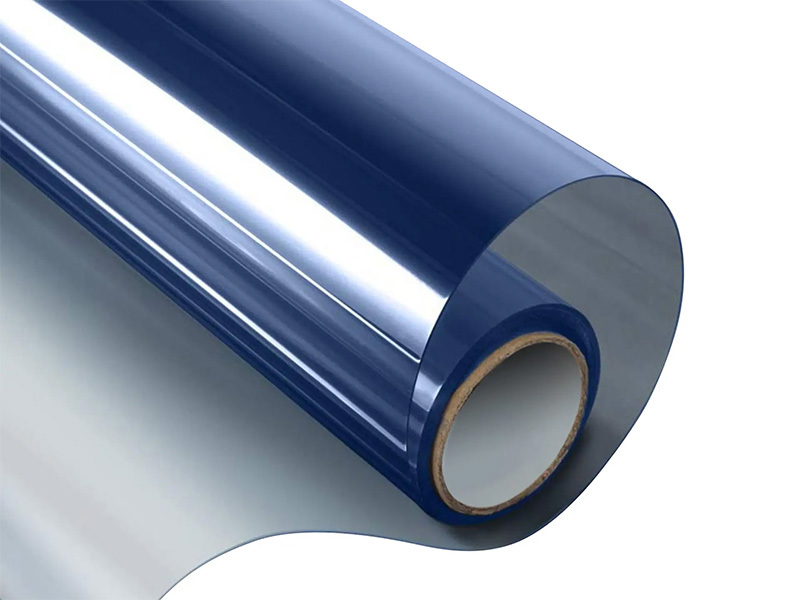

Characteristics and application fields of PET pre-coating film

11

/

02

2021

Color aluminized film pre-coating application and advantages

06

/

10

2020

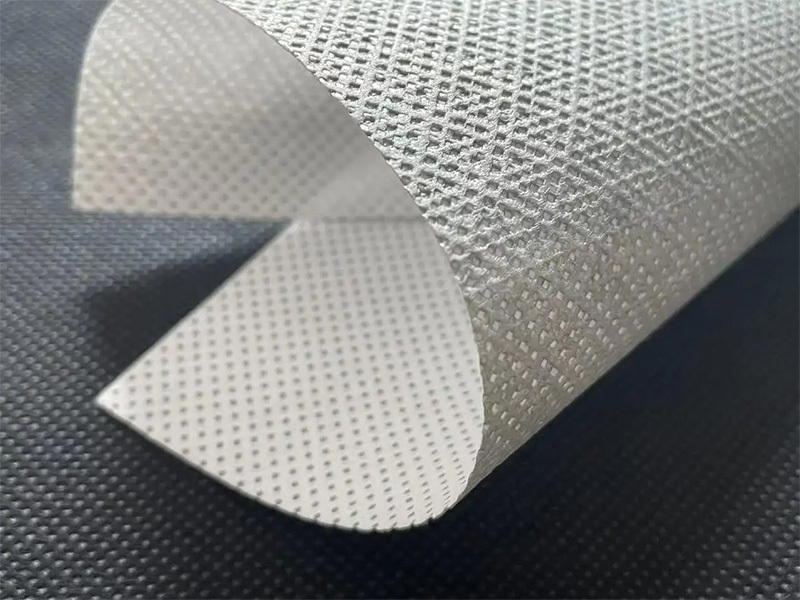

Characteristics and Application of Breathable Membrane

02

/

04

2020